GC in Focus

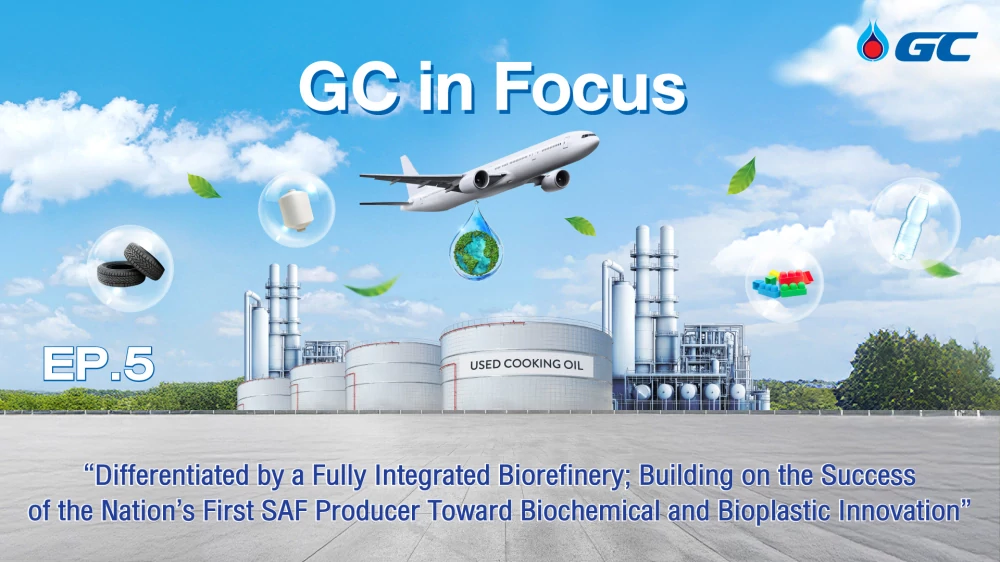

EP. 5: Differentiated by a Fully Integrated Biorefinery; Building on the Success of the Nation’s First SAF Producer Toward Biochemical and Bioplastic Innovation

GC is forging ahead with its fully integrated biorefinery, capable of producing both biochemical and bioplastic products within the same production unit. This underscores the company’s strength in developing high-value, low-carbon businesses that can flexibly meet market demands and serve a wide range of industries.

Building on its early-year success, GC’s biorefinery became the first in Thailand to produce Sustainable Aviation Fuel (SAF) from used cooking oil. This achievement was made possible without constructing a new facility—by leveraging existing expertise and knowledge to develop processes compatible with current refinery units. This approach significantly reduced investment costs compared to building a new plant, while producing SAF that meets internationally recognized standards, including ISCC CORSIA and ISCC Plus certifications.

The SAF produced by GC has already been used in commercial flights operated by Bangkok Airways, marking a significant milestone in developing an environmentally friendly aviation industry. This achievement also helps position Thailand as a regional hub for low-carbon aviation in ASEAN. It reinforces GC’s strategy to expand its High Value & Low Carbon Business, driving sustainable future growth.

Since GC’s production units are fully integrated from upstream to downstream, the outputs from its biorefinery can be further developed into high-value biochemical and bioplastic products. These materials meet the needs of various industries while aligning with the global shift toward sustainable and eco-friendly alternatives.

- Currently, GC has begun commercial production of three key products that serve as high-performance raw materials for multiple industries:

- Bio-Propylene – for the packaging, rigid plastics, toy, and automotive parts industries

- Bio-Butadiene – for tire and sports footwear manufacturing

- Bio-Purified Terephthalic Acid (Bio-PTA) – for polyester fiber, textile, and PET bottle production

In addition, the biorefinery has the potential to produce a wide range of other biochemical and bioplastic products. Once the market is ready, GC can immediately respond to demand. These include Bio-PE, used in the production of packaging, bottles, household items, and plastic films; Bio-Propylene Oxide, for the automotive seat foam, furniture, and insulation industries; Bio-Phenol, for the cosmetics and personal care industries; and Bio-Benzene, for use in the energy sector, basic chemicals, and electronic components industries.

Using renewable resources, such as used cooking oil, as feedstock to produce a wide range of high-value products aligns with the circular economy concept, which emphasizes the efficient and sustainable use of resources, a principle that GC has long upheld. It also supports the BCG (Bio-Circular-Green) Economy model. The fully integrated biorefinery not only reflects GC’s innovation, expertise, and long-standing experience in transforming its existing refinery into a biorefinery without the need for new construction but also demonstrates the company’s strong commitment to conducting business responsibly toward the environment, with the ultimate goal of enhancing quality of life for people in society.